- BAE Systems, Glasgow

Great progress at our BAE Project in Glasgow, thanks to our team, our supervisors and our client that worked together with us to coordinate deliveries, have areas available to unable us to install for last 4 months 2350 tonnes of reinforcement and the overall scheme is well ahead on the program.

Looking forward into 2024 as we are halfway through to continue at the same paste to meet all the requirements such as safety, quality and production at this major landmark project that will contribute to maintain future security of the United Kingdom.

- Glasswater Locks, Birmingham

Our scope of works is to complete the reinforcement to frame structures from the ground up to Blocks E1 – E4 8 floors each, in addition to the RC basement box to Blocks E1 – E3.

There will be involved circa 2000 tonnes of reinforcement over a 54-week programme.

Up to date 3 slipforms are complete with basement box and 3 floors at block E1.

Looking forward into next year to maintain our high standards on safety, quality and productivity to meet all the requirements of our client and main contractor Berkeley Homes which are one of the highest in the industry.

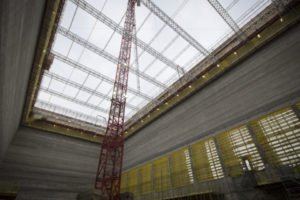

- Coop Live Arena, Manchester

This scheme comprises of foundations, Core bases, complex capping beam, retaining walls, ground floor slabs, upper floors of the arena and roof. 1500 tonnes of reinforcement have been placed throughout the project up to date.

- Lostock EFW, Northwich

This scheme comprises of fifteen structures, including the waste bunker with slipform walls, boiler hall, turbine hall, tipping hall and associated buildings. 3200 tonnes of reinforcement have been placed throughout the project up to date.

- SOYO, Leeds

SOYO is the £300 million pound project creating a new neighbourhood at the heart of Leeds’ cultural quarter. The development is transforming the views along the Headrow within the city, and borders some of the city’s largest and most creative establishments including Leeds Playhouse, Leeds College of Music, BBC Studios and Northern Ballet. This scheme is done if different phases and we have been involved on all of them in the last 4 years. 3500 tonnes of reinforcement have been placed throughout the project up to date in structures such as foundations, slipform walls, PT and traditional slabs etc.

All posts by kupadmin

Skeleton Grange EFW in Leeds and Westfield EFW in Scotland

Very proud and thankfully of our teams that managed to carry out successfully 3 EFW Bunkers slipforms 24hrs working during November and December 2022.

Skeleton Grange EFW in Leeds and Westfield EFW in Scotland started and completed exactly the same time 7th to 21st November.Each of them needing 15-25 steelfixers for each shift for 2 weeks requiring 100 extra steelfixers in total on top of other usual activities around each site. Big thank you to our supervisors, our clients that worked together with us and every operative involved in this major task to carry out these works in a such short time with highest standards on safety, quality and productivity.

Kelvin EFW in Birmingham, Bunker slipform was done between 5th to 18th December on a very cold weather with temperatures between -5 to -10 degrees celsius each day. Thanks to our dedicated supervisors and all the teams on each shift that made this happen on such a difficult condition. Other thanks go to our client that decided to get hot water concrete from the supplier to unable to pour continuously 24hrs for 2 weeks

on a such cold weather.

Steelfixing works were done to highest standards on every aspect

Delighted to achive gold status on Constructionline

Our teams are taught that it is never acceptable to take short cuts, rush, or complete unplanned works that places themselves or others at risk. It’s not just about simply reducing the number of reportable workplace accidents but to improve the overall health and wellbeing of our people both at work and at home.

2020 – Covid19…. However we came through strong and exceeded all expectations.

It has been very challenging & unpredicted year with COVID-19 restrictions and everything else going on. Credit to hard work of each team on each site and high standard of management we have been able to deliver all our projects as planned and have exceeded client’s expectations.

We are delighted to announce completion successfully to the list of projects nationwide.

- Aberdeen NESS, Energy from Waste.

Total tonnage so far 2250t fixed in less than 4 months, with 500t on slipform walls. Work package includes foundations, ground floor slabs & slipform walls. - Earls Gate, Grangemouth, Energy from Waste

Tonnage 1500t

Work package includes foundations, ground floor slabs & jumpform walls. - University of Stirling

Tonnage 450t

Work package includes foundations, ground floor slab, walls, columns and 3 suspended slabs. - Parabola, Edinburgh Park

Tonnage 1200t

Work package includes foundations, ground floor slab, walls, columns and 5 suspended slabs. - Haymarket, Edinburgh

Tonnage 2000t

Work package includes foundations, ground floor slab, walls, columns, jump form & slipform cores and podium suspended slab. - Selkirk, Galashiels Water Tank

Tonnage 700t

Work package includes foundations, ground floor slab, walls, columns and roof suspended slab - SOYO Quarry Hill, Leeds

Tonnage 1350t

Work package includes foundations, ground floor slab, slip form walls, columns and 18 PT floor slabs. - The Christie Hospital, Paterson, Manchester

Capping beam & Substructure works– 1150t

Large capping beam & basement with 1.2m deep raft slab & lining walls completed, 5 big cores & 10 floors designed with bamtec ongoing.

Another busy & successful year past, looking forward to New year 2020

Another busy & successful year past, looking forward to New year 2020. We are delighted to announce completion successfully to some landmark projects nationwide and many more on the way.

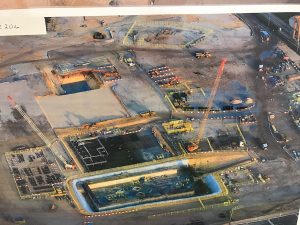

- Woodsmith Mine phase 1, Whitby total tonnage so far 2300t, Work package included; foundations, shafts 40m deep, slipform 140m, production and service shafts with complex winders.

- St Johns Quarter, Manchester -Substructure works– 2150t over 5 months period. Two stories basement with 1m deep raft slab, Lining walls, 3 big cores, level -1 slab and transfer ground floor slab.

- Keadby 2 Power Station, Donchaster – 2530t over 6 months period. Challenging German design, Big foundation plinths with funny shapes, 6 slipforms etc.

- Longwater Avenue, Reading – 450t substructure works, core bases, pile caps &

ground beams.

New High Profile Prestigious Projects

We are delighted to announce that we have been appointed by our clients to carry steelfixing works at some of the biggest investments in the UK.

1-“RAF Lossiemouth Airport” is one of the biggest investments in Scotland as a response from UK and USA to increasing “Russian threat”

2-“Woodsmith Mine – Sirius Minerals” is the biggest project outside London of £2.4 billion creating thousands of jobs in the area.

3-“Birmingham University” investment of full transformation of the University.

New Training for Supervisors Gold Card

After successful completion with NVQ blue cards, we have placed all the supervisors on another management training for Gold Cards which keeps us well ahead on the industry with safety, skills and management training.

Completion of Prestigious Projects

We are delighted to have completed steelfixing works at some of the most prestigious projects like Ferrybridge Multifuel 2, Miller Hill Energy for waste along with many others residential projects around the country and looking forward positive for the new year with many more in the pipeline.

Ferrybridge Multifuel 2

We are very proud to announce to have successfully delivered steel fixing work at the biggest slip form in Europe. We would like to thank all our team for the hard work and long hours to complete this project. With the dedication and determination of our staff we made sure the project happened without any delay or issue. Please view the selection of our photos from the project below. 750t of steel have been fixed over continuous 10 days & nights 24-hour shifts.

More information on the project please view here – http://multifuelenergy.com/fm2/

Training Success

2016 has been a highly successful year for Kupa Steelfixing Ltd with several prestigious projects now completed. The company have also undergone several training schedules throughout the year. All the remaining steel fixers were placed to complete their NVQ. In total 50 steel fixers were trained by Competence Matters during November.

This year the company also had another 15-foremen trained for 2 days on an SSSTS Supervisors course which brings them up to date with every 4 steel fixers now having a fully trained supervisor working alongside them. Kupa Steelfixing Ltd will be finishing 2016 having all steel fixers registered with an NVQ level 2, 22 foremen with SSSTS training, 3 with SMSTS 5-day course, and 3 first aiders.

The company have also kept up to date with construction line, meeting all their requirements.